Perfect Precision: Rotary Airlock Valve Design Reduces Air Loss

The rotary airlock valves are very important in industrial systems where preserving airflow control is necessary. These devices provide a perfect combination of dependability and efficiency as they are meant to control material flow and guarantee little air leakage. Whether in dust collecting systems or pneumatic conveying, they provide constant pressure levels—a necessary condition for flawless functioning. The valve design’s accuracy and efficiency define it as a necessary part of stopping air loss, increasing output, and lowering energy expenses. Let’s investigate how creatively this design keeps air loss under control.

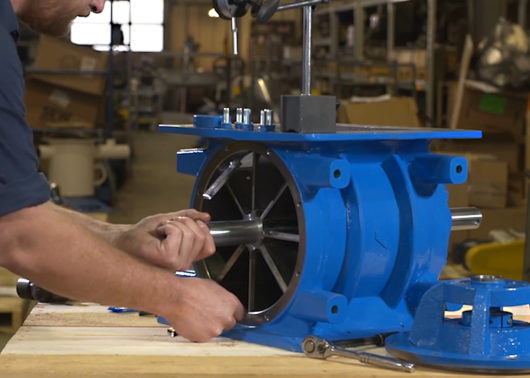

Rotary Airlock Valves: Their Mechanism

Usually featuring vanes or blades, the spinning rotor of the rotary airlock valve drives everything. The rotor shuttles elements between two distinct pressure zones as it revolves. The secret to this operation is how the valve controls to allow the substance to flow through and simultaneously stops any air leakage. Carefully designed to be small enough to reduce air loss without limiting material movement, the rotor and the housing gap is This design guarantees the integrity of the pressure differential when bulk material is passed through the system, so it is perfect for systems needing airtight conditions.

Value of a close seal

The efficacy of the rotary airlock valve in stopping air loss depends critically on its tight seal. The near clearance between the rotor blades and the housing generates the seal. The item being handled will also help to improve the seal by filling up any small gaps and sometimes adding dust or fine particles. This reduces air leakage, therefore enabling improved system airflow control—which may be particularly crucial in dust collecting and pneumatic conveying uses.

Improving System Competency

The design of these valves greatly increases the general system efficiency by eliminating needless air leakage. Controlling air loss helps systems to run at the proper pressure levels using less energy. This increases system functionality and over time helps to lower running expenses as well. The rotary airlock valve is a wise purchase in industrial systems as less air escaping allows the system to run at ideal efficiency without overcompensating.

In essence, preserving system integrity and controlling airflow depends on the way rotary airlock valves are designed. These valves guarantee minimum air loss, therefore enhancing system efficiency, lowering energy usage, and finally helping to enable smoother, more reasonably priced operations. They remain a vital instrument in many industrial uses where controlling air pressure is crucial by providing a constant seal and precisely regulating material flow.